Innovating your ideas

Product design

Whether you are an individual inventor with a brilliant new idea, or an innovative multinational plc, we are able to work with you to develop your idea and ensure its success. We take your design brief through Concept Design to Detail Design and into Manufacture.

We use a proven design process to identify and specify the true needs of the product before even starting any drawing work. With that firm foundation we can confidently produce concept designs for your approval. Our design review process in line with BS7000 ensures the design matches your requirements.

We are different to other designers. We apply engineering from day one, so your product will be functional and cost-effective to manufacture as well as looking great. We use a flexible array of suppliers and manufacturers. We don’t have in-house fabrication so we don’t design your product to keep our shop floor busy. We design it using the optimal manufacturing method for your needs.

I came to Chelker to design and develop a novel device from some basic ideas that had emerged from my lab. The concepts they produced were truly innovative and they helped me through the decision-making process. Chelker has managed every stage of the process from design to production with complete competence and consummate skill.

Professor Emeritus Tim Jacob

Cardiff University

PRODUCT DESIGN CASE STUDIES

-

KODOBIO SENSORY THERAPY

LEARN MORECONSUMER PRODUCT DESIGN FOR A NEW PSEUDO-MEDICAL SENSORY THERAPY

-

BT WIRELESS CITIES

LEARN MORERUGGED ELECTRONICS PACKAGING DESIGN AS STREET FURNITURE

-

CREATE 3D

LEARN MORE3D CAMERA SYSTEM

KODOBIO

SENSORY THERAPY

In 2012 Chelker was approached by Professor Tim Jacob of Cardiff University who had developed a revolutionary new therapy, combining light and aroma, which had the potential to treat depression without the use of drugs. Chelker were given a blank sheet of paper and asked to come up with the physical design for a device to deliver the therapy.

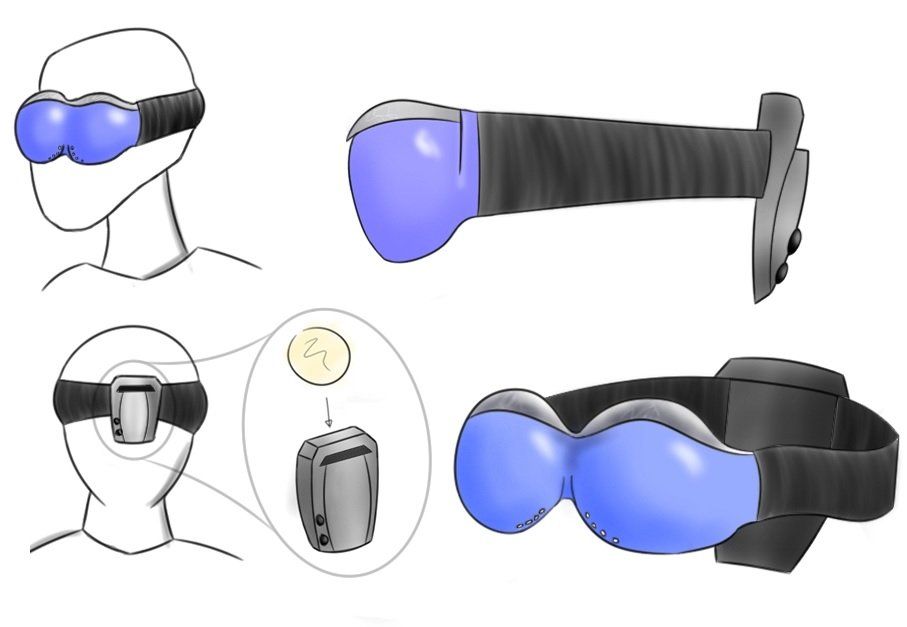

Applying our standard design methodology, and using various design synthesis techniques, Chelker came up with a wide range of solutions that were discussed and refined with the client before focussing on one approach, a head worn goggles device known as Kodobio-G.

The design concept was refined into a working solution. With our electronics partners and an optical designer, we developed the goggles on time and to a fixed budget, and went on to build five prototype units. These prototypes were used successfully for research purposes and market assessments.

Based on the outcomes from the research and marketing, a new project began in 2015 for a device to deliver the therapy as a free-standing visor unit, without user contact, for use in a health and wellness environment. The new product, called Kodobio-V, was launched at the NEC in October 2015.

"I came to Chelker to design and develop a novel device from some basic ideas that had emerged from my lab. The concepts they produced were truly innovative and they helped me through the decision-making process towards a final design and then produced the prototypes. I was enormously pleased with their work. The prototypes enabled me to carry out some important further research studies after which we moved into the second stage of development towards a production model of the device. The final product – the Kodobio – which has linked optics, electronics, electronic and mechanical design, exceeded my expectations and has impressed everyone who has seen it including the most sceptical of my critics, my family! Chelker has managed every stage of the process from design to production with complete competence and consummate skill.”

Professor Emeritus Tim Jacob

Cardiff University.

BT

METROSCAPE

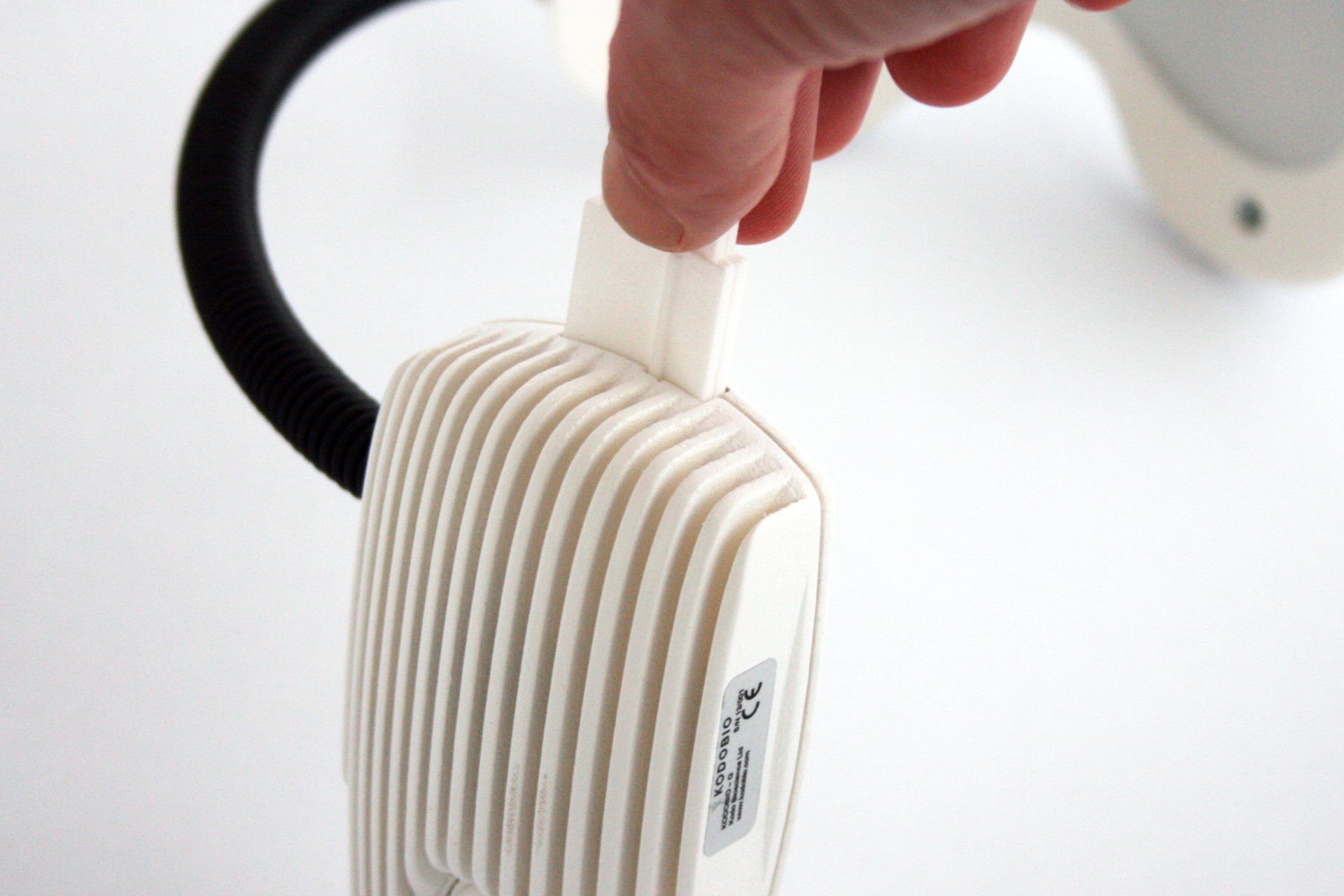

BT is the world’s most established communications company employing 90,000 people across 170 countries. At Long Hanborough, near Oxford, BT iNet was looking for someone to innovate and manufacture a series of wireless internet units based around PC-104 cards including the Cisco 3200 Series Mobile Access Router. The units would be deployed in the street as part of the BT Wireless Cities project, and needed to be ruggedly designed to operate reliably from a poor quality lamp-post power supply, withstanding temperature extremes from -25C to +85C, and weatherproofed to IP67.

Using our experience gained in the defence industry, Chelker developed a unit that met the required specification, carrying out full environmental, EMC and CE testing. We developed a bespoke aluminium extrusion housing that enabled conductive (fanless) cooling of the boards. As well as fully documenting several variants of the design, including one type for military use, Chelker manufactured the units in conjunction with our electronics partners, managed software configurations, and developed cable harnesses and power converters suited to the environment.

With over 1000 units built, Chelker continues to support units in the field with spares, repairs and replacements in accordance with an agreed SLA (Service Level Agreement).

CREATE 3D

PhotoScanner

Create3D are a technology company who have innovated a system for 3D photography using a normal digital camera. Create3D asked Chelker to design and develop a linear motion camera platform.

Called PhotoScanner, it works by moving the camera along a linear track under computer control, programmed from a smart phone via Bluetooth. The camera trigger is fired electronically during a scan run, ensuring that images are captured at the right position, with a linear resolution of 0.1mm.

Once the images are captured they are uploaded to Create3D who print them using a special process, with stunning 3D hologram-like results that can be viewed without special glasses. The technique can be used for portraits, landscapes, still life, advertising, in fact anything you may like to take a picture of.

Chelker took the requirement from concept right through to manufacture, managing the production of an initial prototype system and also a full batch of finished units. The design involved a bespoke aluminium extrusion, stepper motor control using a low cost PLC, and a dedicated microprocessor for high speed shutter control.

Registered office

Moorside House, Farling Top, Cowling, North Yorkshire, BD22 0NW, UK

Chelker Design Ltd

Registered in England and Wales No. 12055703

VAT No. 1325 4736 02

Chelker Automation Ltd

Registered in England and Wales No. 12055666

VAT No. 326 0396 14